This product is designed and tested for installations to finished floor level (FFL), Operating as a door.

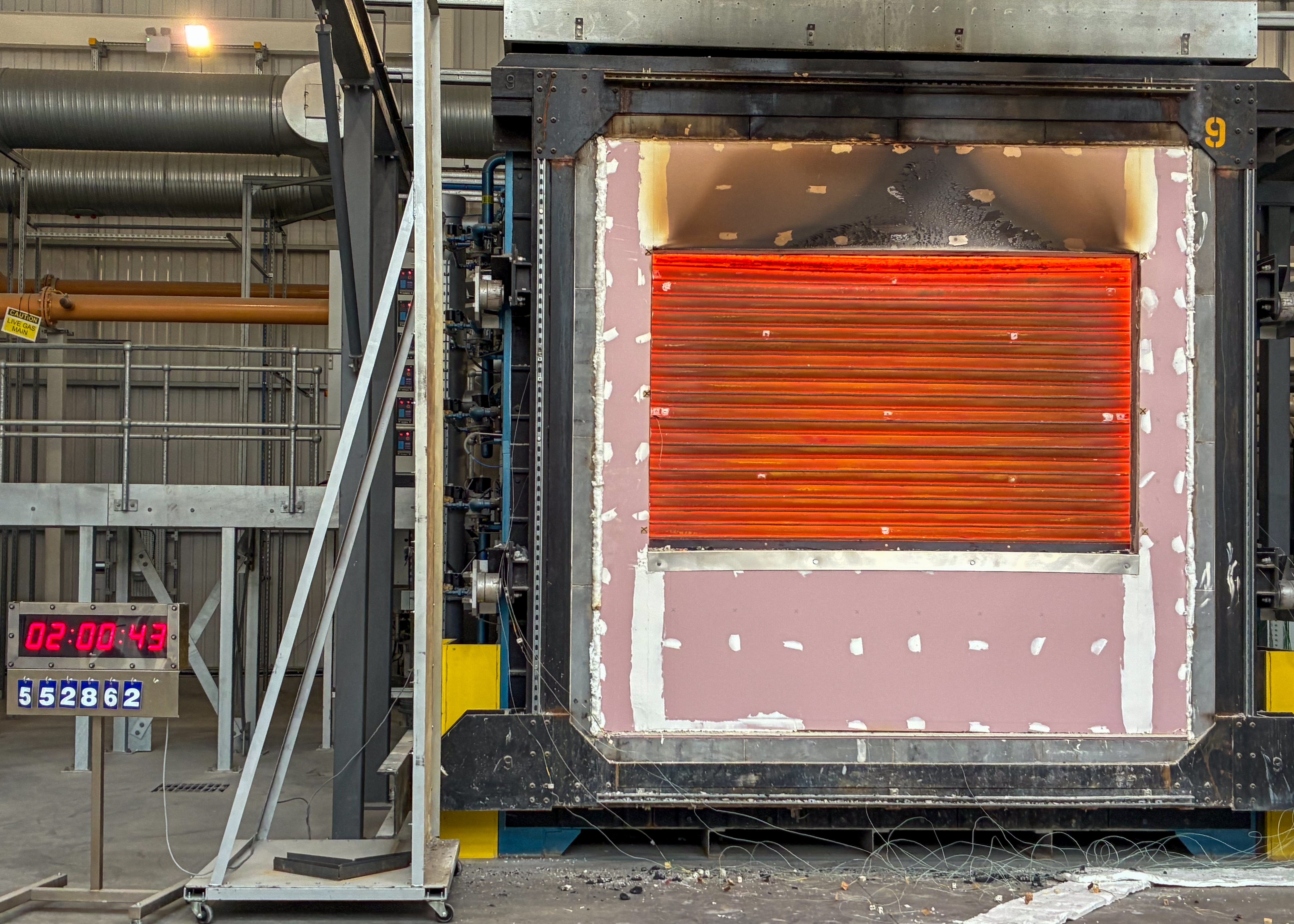

Manufactured to the highest quality and tested to the latest standard BS EN 1643: 2014 + A1: 2018, our Flame Armour™ (Doorset) roller shutter assemblies offer up to four hours of integrity performance (classified in accordance with BS EN 13501-2 for E30, E60, E90 and E240 performance ratings).

This product range is fully CE and UKCA marked in accordance with the product standard BS EN 16034: 2014 and permitted to be installed into masonry, timber stud partitions and protected structural steel supporting constructions.

Covered by the following Certification Bodies:

- Warringtonfire Testing and Certification Ltd (Approved Body No. 1121) – UKCA Certificate No. RA7003

- Element Materials Technology Rotterdam B.V. (Notified Body No. 2812) – CE Certificate No. RA5006

Flame Armour (Doorset) Fire Shutters Scope:

✓ Integrity performance for up to 4 hours (E240 ratings)

✓ CE & UKCA Marked for full compliance with Building Regulations

✓ Furnace Tested to EN 1634-1:2014 + A1: 2018 (superseding BS 476: Part 22: 1987)

✓ Manufactured in accordance with Warringtonfire Extended Application Report No. 416673

✓ Classified in accordance with the latest classification standard BS EN 13501-2: 2023

✓ Certified in accordance with BS EN 13241:2003 + A2: 2016 and BS 16034: 2014 standards

✓ Gravity fail-safe motor option: Closes automatically in case of fire or power failure

✓ Suitable for ‘Rigid’ & ‘Flexible’ supporting constructions (as defined within EN 1363-1)

✓ Offering both tubular and inline (chain-driven) industrial motor applications.